Inspections, troubleshooting, and documentation are essential responsibilities of aircraft maintenance engineers.

In order to keep aircraft flying around the clock, aircraft maintenance engineers must work continuously. Most aviation maintenance sites operate three shifts in a 24-hour period. Aircraft engineers typically begin their day by reviewing ongoing work schedules, task lists from previous shifts, and maintenance records.

Incoming work briefings and shop floor management (SFM) meetings are generally held at the beginning of the shift. Teams discuss ongoing issues, tasks for the day, and any critical deviations necessary for the ongoing projects. The team also discusses near-term work priorities during the early-shift briefings. Aircraft engineers gather sufficient information about the tasks for the day and begin their plan of action.

Inspection and troubleshooting

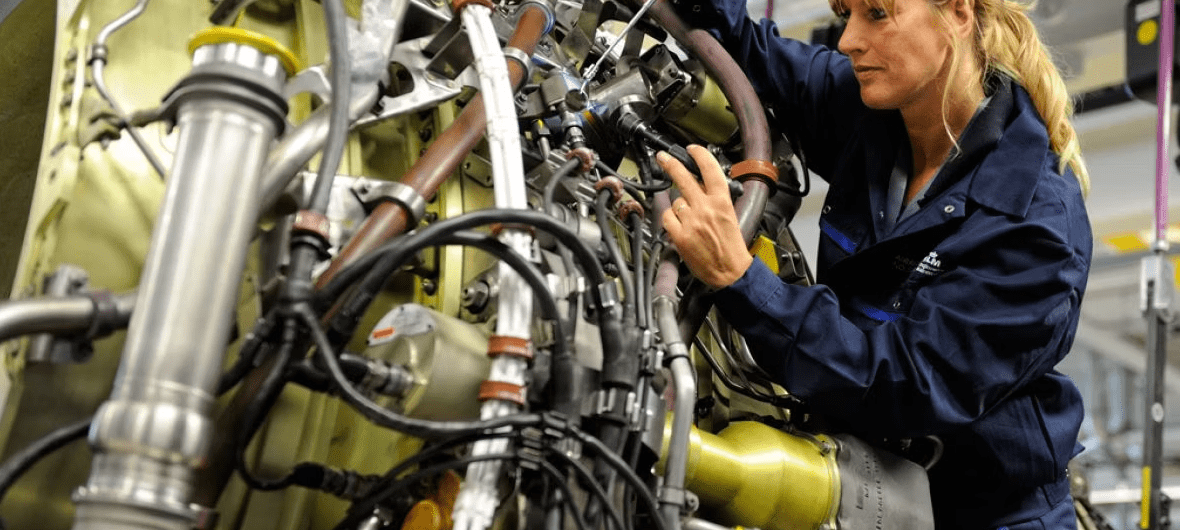

In most areas of maintenance work, engineers are responsible for inspecting various parts of the aircraft. Whether an exterior review of the airframe or a more detailed piece-part inspection, engineers are relied upon for critical diagnosis of aviation components. Depending on the priority of tasks, an aircraft engineer may spend the first few hours of the day inspecting parts using various digital and manual tools.

For example, during an aircraft overhaul, engineers and technicians will inspect the engines, landing gear, as well as control, hydraulics, and electrical systems, among other things. The idea is to examine individual parts, assemblies, and systems to identify whether they adhere to safety standards.

Photo: industryviews/Shutterstock

As one of the most regulated industries in the world, aviation maintenance requires strict safety standards and compliance by aviation companies and personnel. Once the components are identified and deemed repaired, it is time to begin the maintenance work.

Aircraft maintenance

Aircraft maintenance is an ongoing work that may take anywhere between a few days to a few months, depending on the extent of what’s required. Based on scheduled maintenance programs, aircraft engineers perform any other necessary repairs and initialize preventive maintenance measures. While some parts and systems can easily be replaced during maintenance, others may require repair work such as machining, blending, or coating.

For example, during a C check, a heavy system maintenance program, aircraft engineers test pumps, actuators, and functional assemblies for performance and failure. Moreover, load-bearing components such as the fuselage structure, wings, and engine pylons are examined and tested for wear and stress.

Aircraft engineers also conduct system checks at each subsystem level to ensure compliance with regulatory requirements. It is noteworthy that aircraft maintenance engineers work closely with shop floor mechanics and technicians to address maintenance needs. Moreover, several Quality Assurance individuals are involved in consultation on the quality compliance and acceptance of critical maintenance tasks.

The documentation may include work scope reports, inspection records, maintenance records, serviceability documentation, and compliance with the airworthiness certification. The maintenance facility or aircraft operator can be audited to provide a complete history of an aircraft at any time during its lifetime.

Source: Simple Flying